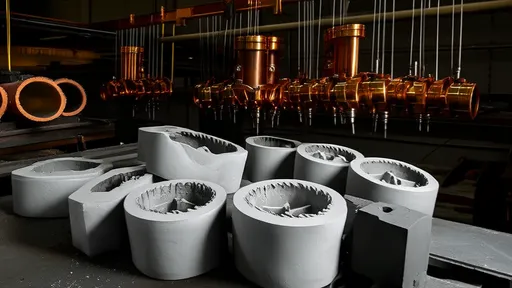

The lost-wax casting process, an ancient technique refined over millennia, remains a cornerstone of precision metalworking. Among its many variables, the water-to-plaster ratio in investment molds and its relationship to shrinkage rates represent a critical yet often overlooked aspect of production. Foundries and artisans alike grapple with balancing these factors to achieve dimensional accuracy while maintaining mold integrity.

At the heart of the matter lies the paradoxical nature of plaster investments. As water content increases, the mixture becomes more fluid and easier to pour, capturing intricate details from wax patterns. However, this apparent advantage comes at a cost. Higher water ratios lead to increased porosity in the cured mold, creating microscopic channels that allow gases to escape during metal pouring but also contributing to greater overall shrinkage. The relationship isn't linear - small adjustments in hydration can produce disproportionate effects on final dimensions.

Seasoned casters develop an almost intuitive understanding of how different plaster brands and batches behave. Industrial formulations often include proprietary additives that modify crystallization patterns, while traditional pottery plasters follow more predictable but less controllable drying characteristics. The period between mold creation and burnout proves crucial, as uneven drying rates between surface and core layers can induce stress fractures or warping before molten metal ever touches the investment.

Modern measurement techniques have revealed surprising nuances in shrinkage behavior. Contrary to early assumptions, the majority of dimensional change occurs during the dehydration phase rather than metal solidification. Thermal expansion coefficients of the plaster matrix interact with the cooling metal in complex ways, sometimes compensating for earlier shrinkage or, in worst cases, exacerbating distortion. This explains why seemingly identical casting setups can produce varying results under different humidity conditions.

The wax pattern itself plays an unexpected role in this equation. Certain sculpting blends contain fillers that absorb moisture from wet investment, subtly altering local plaster density. This phenomenon creates microscopic variations in shrinkage rates across a single piece, particularly problematic for large-scale castings where cumulative effects become visually apparent. Some studios now precondition wax models in climate-controlled chambers to stabilize moisture content before investment.

Practical solutions have emerged from generations of trial and error. Many European bronze foundries employ a stepped hydration approach, using richer mixtures for initial contact coats followed by more diluted batches for backup layers. This hybrid method preserves surface detail while reducing overall shrinkage stress. Japanese metalworkers developed an alternative technique incorporating rice husk ash into plaster blends, creating microstructures that channel moisture evenly during drying.

Digital fabrication has introduced new variables into this ancient equation. 3D-printed resin patterns behave differently than traditional wax when surrounded by setting plaster, sometimes creating interfacial tensions that amplify shrinkage effects. Contemporary research focuses on developing plaster formulations specifically engineered for digital casting workflows, with modified particle geometries that accommodate resin's unique thermal properties.

The artistic implications of these technical considerations shouldn't be underestimated. Master casters sometimes intentionally manipulate water ratios to create controlled distortion for aesthetic effect. Certain African bronze traditions exploit differential shrinkage to produce signature surface textures impossible to achieve through mechanical means. This blurring of technical limitation and creative opportunity exemplifies the living evolution of lost-wax casting as both science and art.

Laboratory analysis continues to uncover unexpected relationships between plaster chemistry and metal behavior. Recent studies show that calcium sulfate dihydrate formations in certain plasters can actively interact with molten alloys, creating transitional zones that affect cooling rates. These findings challenge conventional wisdom about the passive nature of investment materials, suggesting plaster composition may influence metallurgical properties beyond simple dimensional control.

For production foundries, the economic impact of shrinkage miscalculation can be severe. Aerospace components requiring ±0.1% tolerances demand different approaches than sculptural pieces where 2-3% variation might be acceptable. Many industrial operations now employ real-time moisture sensors in mixing rooms, correlating viscosity readings with historical shrinkage data to predict outcomes before pouring occurs. This data-driven approach reduces scrap rates but requires substantial upfront investment in monitoring equipment.

The craft tradition maintains alternative wisdom. Venetian glassmakers adapting lost-wax techniques for vitreous pours discovered that adding crushed volcanic ash to plaster mixtures reduced shrinkage cracking in delicate forms. This empirical knowledge, passed through generations of furnace workers, only recently found scientific explanation as the ash particles providing nucleation sites for more even crystal growth during plaster setting.

Future developments may radically alter current practices. Nanotechnology researchers are experimenting with graphene-doped plaster investments that demonstrate unprecedented dimensional stability. Early tests show shrinkage reductions up to 60% compared to conventional formulas, though cost remains prohibitive for most applications. Meanwhile, ecological concerns drive experimentation with biodegradable alternatives to traditional plaster, creating new variables in the eternal quest to balance fluidity against fidelity.

What becomes clear across all these perspectives is that water-to-plaster ratio represents far more than a simple recipe adjustment. It's a dynamic negotiation between physical laws, material properties, and intended outcomes - a fundamental dialogue that has shaped metal casting since the first artisan pressed clay around a beeswax form. The shrinkage rates we measure today continue ancient conversations about how substances transform from one state to another, and how human ingenuity bridges the gaps between expectation and reality.

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025