The world of luxury watchmaking thrives on precision, durability, and the relentless pursuit of perfection. Among the many intricate components that define high-end timepieces, the serpentine spring—often referred to as the Bulgari Serpenti spring due to its iconic design—stands out as a marvel of engineering. Recently, Bulgari has undertaken rigorous fatigue limit testing on these springs, pushing the boundaries of material science and horological innovation. The results not only reaffirm the brand’s commitment to excellence but also shed light on the fascinating interplay between design and endurance in mechanical watchmaking.

At the heart of the Serpenti collection lies a coiled spring that mimics the sinuous form of a serpent. This spring is not merely an aesthetic flourish; it serves a critical functional role in the watch’s movement. Over time, however, even the most resilient materials can succumb to the stresses of repeated compression and expansion. To ensure that the Serpenti spring maintains its integrity over decades of use, Bulgari’s engineers have subjected it to exhaustive fatigue testing. These tests simulate years of wear in a matter of weeks, exposing the spring to extreme conditions that would challenge even the most robust alloys.

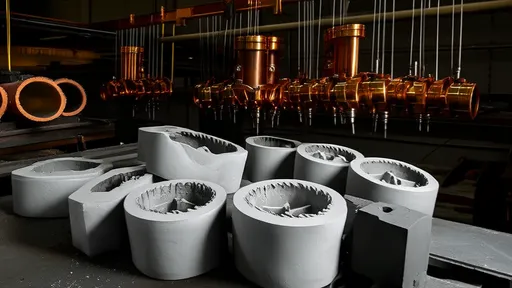

The methodology behind Bulgari’s fatigue testing is as meticulous as the craftsmanship of the watches themselves. Using advanced machinery, the springs are cycled through millions of compressions, each one meticulously monitored for signs of weakening or deformation. High-speed cameras and sensors capture microscopic changes in the spring’s structure, allowing engineers to pinpoint potential failure points long before they become apparent in real-world use. This proactive approach ensures that every Serpenti spring not only meets but exceeds the stringent standards expected of a luxury timepiece.

One of the most striking findings from the fatigue tests is the spring’s remarkable resilience. Even after millions of cycles, the Serpenti spring exhibits minimal degradation, a testament to the high-quality materials and precision engineering that define Bulgari’s creations. The alloy used in the spring, a closely guarded proprietary blend, has been optimized to resist the twin foes of fatigue and corrosion. This combination of strength and flexibility is what allows the Serpenti watch to maintain its accuracy and elegance over a lifetime of wear.

Beyond the technical achievements, the fatigue testing underscores Bulgari’s philosophy of blending art with science. The Serpenti spring is more than a functional component; it is a symbol of the brand’s dedication to innovation and longevity. By subjecting their designs to such rigorous scrutiny, Bulgari ensures that each watch is not just a fleeting accessory but a lasting heirloom. The results of these tests are a quiet reassurance to collectors and enthusiasts alike—proof that beauty and durability can coexist in perfect harmony.

The implications of Bulgari’s fatigue testing extend far beyond the Serpenti line. The insights gained from these experiments are likely to influence future designs across the brand’s portfolio, setting new benchmarks for durability in luxury watchmaking. As competitors strive to keep pace, Bulgari’s unwavering focus on quality and innovation ensures that they remain at the forefront of the industry. For those who appreciate the finer details of horology, the Serpenti spring is a shining example of what happens when cutting-edge technology meets timeless design.

In an era where disposable fashion dominates, Bulgari’s commitment to endurance is a refreshing counterpoint. The fatigue limit testing of the Serpenti spring is not just a technical exercise; it is a statement of values. It speaks to a belief in creating objects that endure, both in function and in style. For the discerning wearer, a Bulgari watch is more than a timekeeper—it is a piece of engineering artistry, built to withstand the test of time. And with each passing cycle of the Serpenti spring, that promise is reaffirmed, one meticulous test at a time.

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025

By /Aug 11, 2025